Who We are?

TECHNOPANEL Aluminum Cladding – كلادينج المنيوم تكنوبانل

Technopanel was established in 2006. The first commercial production for the domestic and overseas markets started in 2007 and the first factory to receive the Saudi SASO quality mark.

Production is in accordance with SASO 2752/2008. We have participated with the Saudi Organization for Standardization, Metrology and Quality (SASO) in the development of specifications for insulated aluminum panels in 2008.

Projects

Products

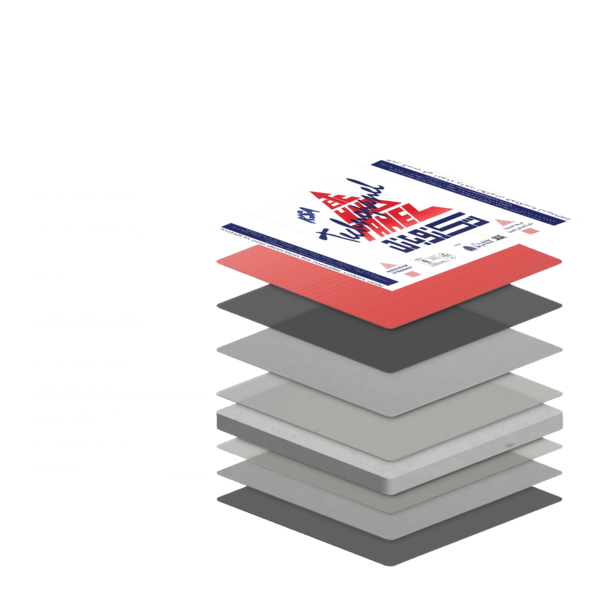

A2-FR Aluminum Cladding

Complies with international fire safety standards to prevent the spread of flames and smoke in fire events. It boasts a high strength-to-weight ratio and excellent rigidity for easy forming and installation. It is resistant to extreme weather conditions, UV exposure, pollution, acid, alkali, and salt, ensuring low maintenance.

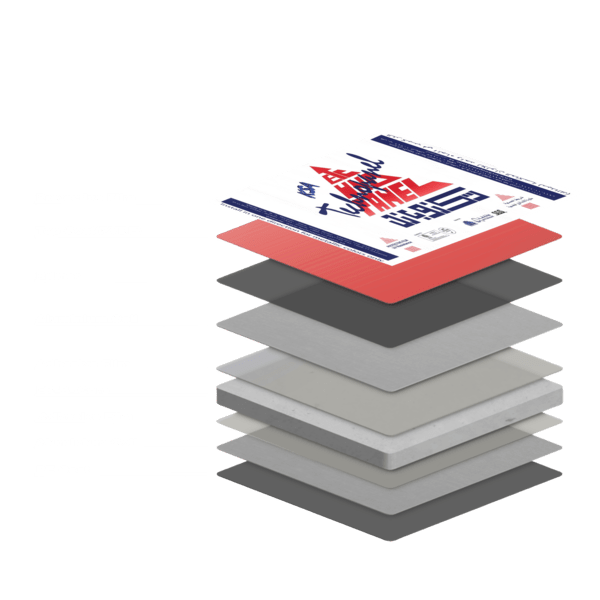

B1-FR Aluminum Cladding

Complies with international fire safety standards to prevent the spread of flames and smoke in fire events. It boasts a high strength-to-weight ratio and excellent rigidity for easy forming and installation. It is resistant to extreme weather conditions, UV exposure, pollution, acid, alkali, and salt, ensuring durability.

Services

We use unique, custom-built tools to give us the edge

A state-of-the-art machinery to meet even the most complex designs. Our three roller bending machines are capable of bending Cladding into circular shapes with a minimum diameter of 25cm and above, and a maximum width of 3.2m. We efficiently provide high-quality circular panels to meet the demands of our clients.

This cutting-edge machine is capable of designing Cladding with maximum length of 6m and a width of 2m per architectural designs, as well as creating intricate and detailed CNC art. our machine is capable of handling most demanding projects with ease. Whether you’re looking to create complex designs or simple cuts for commercial projects and seeking unique pieces of wall art.

We offer the ability to produce customized sizes per custom orders, as well as perform cutting to suit the architectural requirements of projects. Our specialized cutting machine is designed to Cladding with accuracy, delivering clean, smooth cuts for a high-quality finish.

Our manual V-Grooving machine is capable of grooving up to 200 square meters per hour with precision and accuracy. With the ability to perform V-Grooving at angles ranging from 90° to 135°, we can meet the unique needs of our clients. Additionally, our team can manually groove ACP panels with a maximum length of 3 meters and a width of 2 meters.

Our Clients

Get in Touch