المصنع الأول بالمملكة

جودة استثنائية

ألوان تناسب رؤيتك

مشاريعنا تصنع التأثير

نحن هنا لنساعدك

تعرف على تكنوبانل، بين الخبرة العريقة في انتاج الكلادينج منذ عام 2006 و مواكبة احدث التطورات التكنولوجية في الصناعة، تعرف كيف نسعى لتقديم الأفضل لك في الجودة و التميز

اكتشف كيف نقدم جودة لا مثيل لها للكلادينج المقاوم للحريق بكونه أول كلادينج بالمملكة يحصل على شهادة الساسو (SASO) و إخضاعه لأكبر عدد من اختبارات الجودة في مختبر مصنعنا

اكتشف خيارات تناسب كل نمط من الألوان فائقة الجودة التي تضمن الفخامة للمبنى الخاص بك و تلائم اسلوبك و متطلبات مشروعك. من الألوان المحايدة الدقيقة إلى الألوان الإبداعية

شاهد كيف شاركنا في نجاح رؤية الأسماء العملاقة من الفكرة حتى التنفيذ

لديك اسئلة ؟ تواصل معنا الآن و دعنا نساعدك في تحويل الرؤية إلى واقع

المشاريع

المنتجات

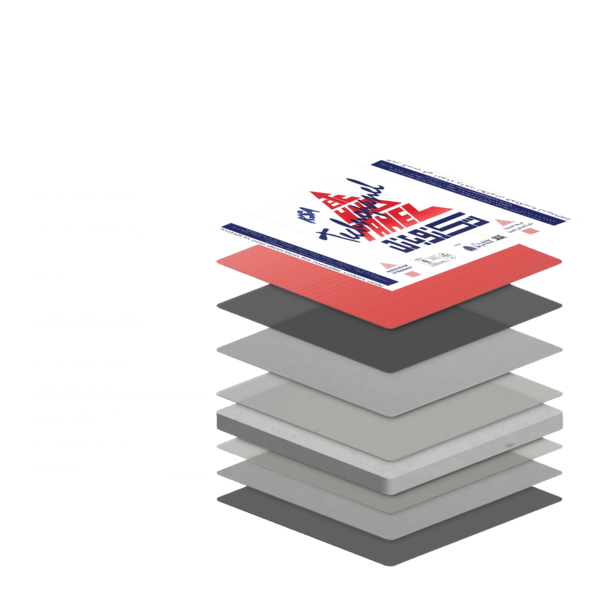

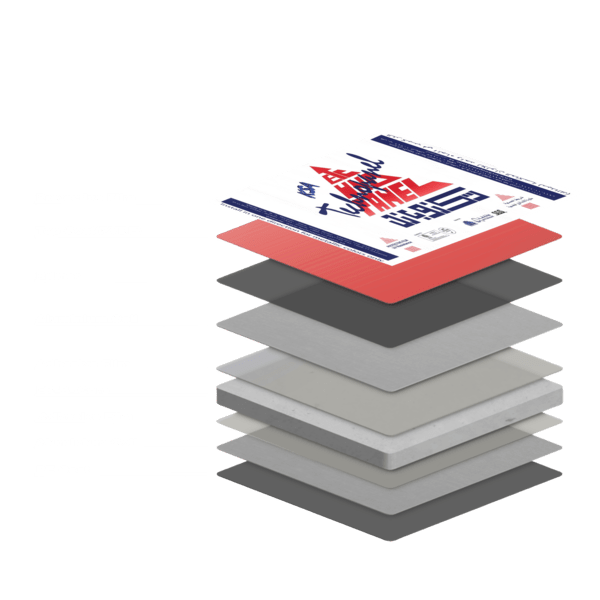

كلادينج الألمنيوم المقاوم للحريق A2 - FR

يتوافق مع المعايير الدولية للسلامة من الحرائق لمنع انتشار اللهب والدخان في أحداث الحريق و تتميز بنسبة قوة إلى وزن عالية وصلابة ممتازة لسهولة التشكيل والتركيب و مقاومة للظروف الجوية القاسية، والتعرض للأشعة فوق البنفسجية، والتلوث، والأحماض، والقلويات، والملح، مما يضمن صيانة منخفضة

كلادينج الألمنيوم المقاوم للحريق B1 - FR

يتوافق مع المعايير الدولية للسلامة من الحرائق لمنع انتشار اللهب والدخان في أحداث الحريق و تتميز بنسبة قوة إلى وزن عالية وصلابة ممتازة لسهولة التشكيل والتركيب و مقاومة للظروف الجوية القاسية، والتعرض للأشعة فوق البنفسجية، والتلوث، والأحماض، والقلويات، والملح، مما يضمن المتانة.

الخدمات

نستخدم أدوات فريدة ومصممة خصيصًا لمنحنا الأفضلية

آلة الحز على شكل حرف V اليدوية لدينا قادرة على الحز حتى 200 متر مربع في الساعة بدقة وإتقان. بفضل القدرة على إجراء عملية الحز بزوايا تتراوح من 90 درجة إلى 135 درجة، يمكننا تلبية احتياجات عملائنا. بالإضافة إلى ذلك، يمكن لفريقنا حفر الكسوة يدويًا بحد أقصى يبلغ 3 أمتار وعرض 2 متر. إن التزامنا بالجودة ورضا العملاء يميزنا في هذه الصناعة.

نحن ندرك أهمية التخصيص في تلبية الاحتياجات الفريدة لعملائنا. ولهذا السبب فإننا نوفر القدرة على إنتاج أحجام مخصصة وفقًا للطلبات المخصصة، بالإضافة إلى إجراء القطع بما يتناسب مع المتطلبات المعمارية لمشاريع محددة. تم تصميم آلة القطع الخاصة بنا لقطع الكسوة بدقة وإحكام، مما يوفر قطعًا نظيفًا وسلسًا للحصول على تشطيب عالي الجودة، بقدرة إنتاجية تبلغ 200 متر مربع / ساعة

نحن فخورون بتقديم مجموعة متنوعة من الخدمات من خلال آلة CNC الخاصة بنا. هذه الآلة قادرة على إجراء القطع والحفر وتصميم الكسوة بطول أقصى يبلغ 6 أمتار وعرض 2 متر وفقًا للتصميمات المعمارية، بالإضافة إلى إنشاء أعمال فنية معقدة ومفصلة باستخدام الحاسب الآلي. تسمح لنا تقنيتنا بإنشاء قطع وأخاديد دقيقة، مما يضمن الحصول على تشطيب عالي الجودة يلبي معايير عملائنا. مع قدرة إنتاجية تبلغ 100 متر مربع في الساعة، فإن ماكينة CNC الخاصة بنا قادرة على التعامل حتى مع أكثر المشاريع تطلبًا بسهولة. سواء كنت تتطلع إلى إنشاء تصميمات معقدة أو قطع بسيطة للمشاريع، وتبحث عن قطعة فنية جدارية فريدة من نوعها.

نحن نقدم القدرة على إنتاج أحجام مخصصة وفقًا للطلبات المخصصة، بالإضافة إلى إجراء القطع بما يتناسب مع المتطلبات المعمارية لمشاريع محددة. تم تصميم آلة القطع الخاصة بنا لقطع الكسوة بدقة ودقة، مما يوفر قطعًا نظيفًا وسلسًا للحصول على تشطيب عالي الجودة، بقدرة إنتاجية تبلغ 200 متر مربع / ساعة.

عملائنا